1、Product characteristics:

This product is a kind of inorganic water-based heat dissipation coating material, through the use of specific inorganic coating material on the surface of the heat dissipation body to form a film, the accumulated heat during the operation of the equipment to the atmosphere, thus inhibiting the temperature rise of the equipment.

2、the advantages of water-based heat dissipation coating:

the heat dissipation coating film has the characteristics of high thermal conductivity and high thermal radiation coefficient, which can solve the problem of not being able to spread heat quickly into the air due to the low thermal radiation coefficient of the material of the heat dissipation device. In addition, the heat dissipation coating can greatly increase the heat dissipation area of the heat dissipation device without changing the heat dissipation installation structure. The larger the area of the heat dissipation device, the better the heat dissipation effect.

3、Scope of application:

Industrial products cooling applications such as: frequency converter, BMS electric drive system

Automotive heat dissipation applications such as: automotive water tank heat dissipation, new energy vehicle battery pack, etc

Consumer electronics cooling applications such as mobile phones/tablets and computers

Home appliances cooling applications such as: air conditioning, washing machines, TV, etc

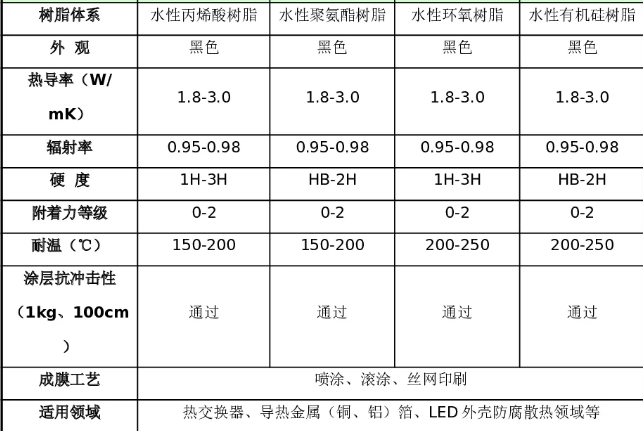

4、paint performance parameters:

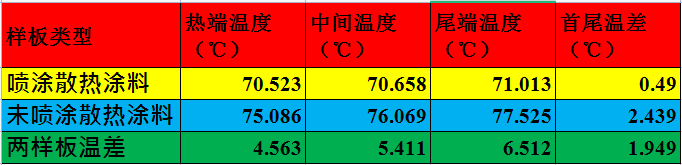

Performance comparison:

The average temperature drop after spraying heat dissipating paint and without spraying heat dissipating paint is 5.5℃, and the temperature difference between the two stages increases from 0.5 to 2.4℃

This means that heat is quickly carried away by the cooling paint.