1. product performance:

High hardness (2H or more), chemical resistance, strong weather resistance, high gloss, yellowing resistance, excellent adhesion, water resistance.

2. Scope of application:

Chassis, cabinet, blinds, household appliance shell, horn net, strong weather resistance, high gloss, good quality and cheap

Used in electroplated parts, electrolytic plates, polished parts, aluminum.

3. Storage conditions

1, the paint storage period is half a year, after passing the inspection can still be used.

2, diluent (solvent) should be sealed and stored, it is recommended that it should be used as soon as possible. Should not be stored too long.

3, the storage temperature of 15-30℃ is suitable for dry, ventilated, cool place away from fire, heat source, to prevent direct sunlight. Store separately from oxidants.

4. Precautions:

1, before use, it is necessary to confirm whether the paint type, specification, quality, color and matching diluent are consistent with the match.

2, before use, it is necessary to confirm the pre-treatment method of the coated material, and the appropriate pre-treatment method must be selected for different coated materials.

3, the paint should be stirred before use, and the painting appliance should be confirmed to be cleaned.

4, the spray viscosity should be adjusted according to the different temperature of the painting environment, and the viscosity is low when the temperature is high.

5. Packing specifications:

4 litres or 20 litres /3.5KG or 18KG.

6. Coating process design:

Coating combination

1, a coating a baking: widely used in the workpiece structure is simple, the material condition is good, the color of the ordinary process.

2. Two coats and one bake: It is applied to the workpiece requiring full coating or defective material or bright color, and some special requirements of the industry, the process uses a specific primer, and the topcoat can be applied without baking after the first construction, and then the one-time drying can be done.

3, two coating two baking: The scope of application is the same as above, mainly due to production line restrictions, primer requirements grinding, and other special factors must be dried in advance before repainting the top paint, in general, the first baking temperature can not be too high, the paint film baking to 70% dry is the best.

4, multiple painting: mainly used in some crafts, antique lighting, bicycle frame, etc., the construction process is basically the same as 2.3 can be selected according to the actual situation.

Note: In the three combinations of 234, special attention should be paid to the matching combination of each coating, so as not to affect the adhesion between the coating films.

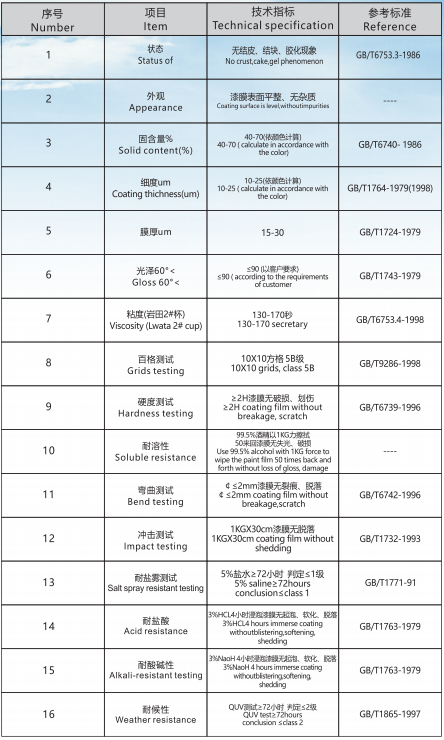

7. Performance technical indicators